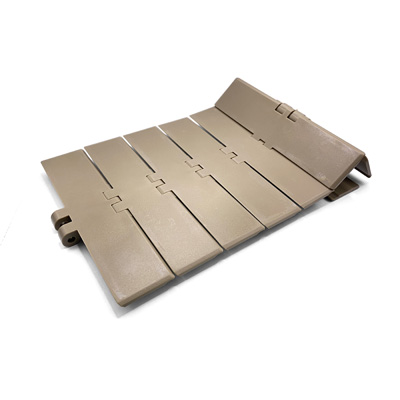

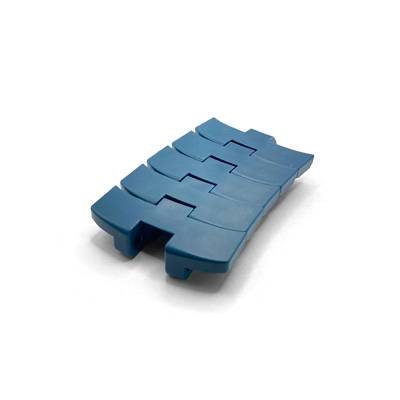

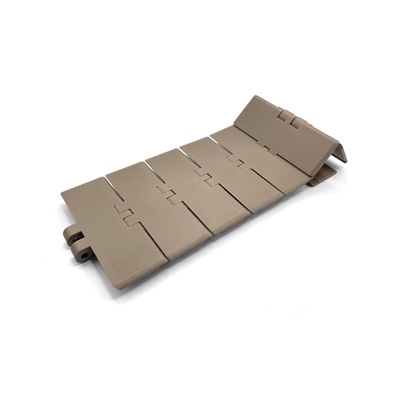

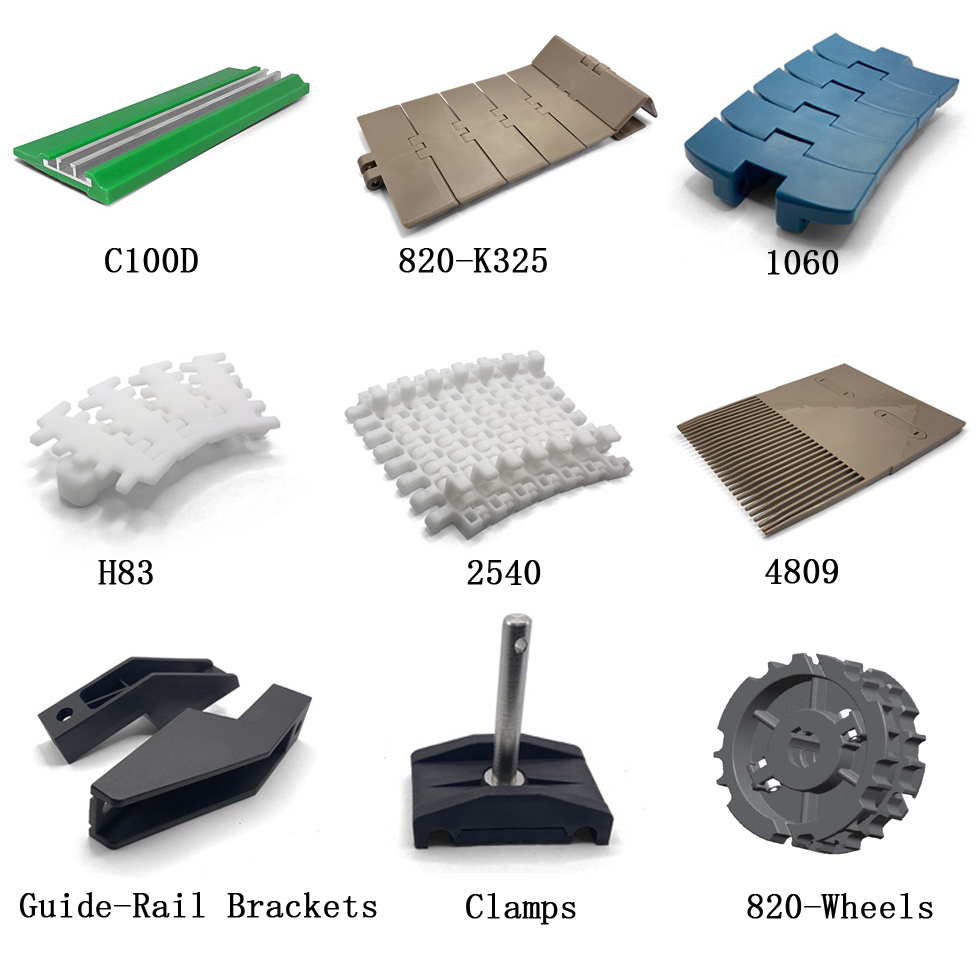

Jetway Inkjet Printers Conveyor Pulley Chain Plate Plastic Belting 820-K600

Product Display

Quick Details

1.Luohe Global modular conveyor belt has more than 10 times service life,long life time and reducing replacement cost than traditional conveyor belt.

Applications

FAQ

1. Q:Are you a factory outlets or trading company?

A:We are a factory outlets.

2. Q:If small order is acceptable? Yes,trial order is welcome!

A:Yes,trial order is welcome!

3. Q:Could you offer us samples?

A:Yes, generally, free sample for 1~2pcs, and the freigt you need to bear.

4. Q:What’s your shipment terms?

A:Generally, if samples, by air or by express; If bigger order by sea.

5. Q:Could you put our logo on the packing?

A:Yes, it is easy to print your logo on the packing.

6. Q:What’s your package?

A:In standard export cartons, but could be designed as your request.

7. Q:What’s your main port of lading?

A:FoShan/GuangZhou/ShenZhen/ShangHai/NingBo.

Packaging and Shipping

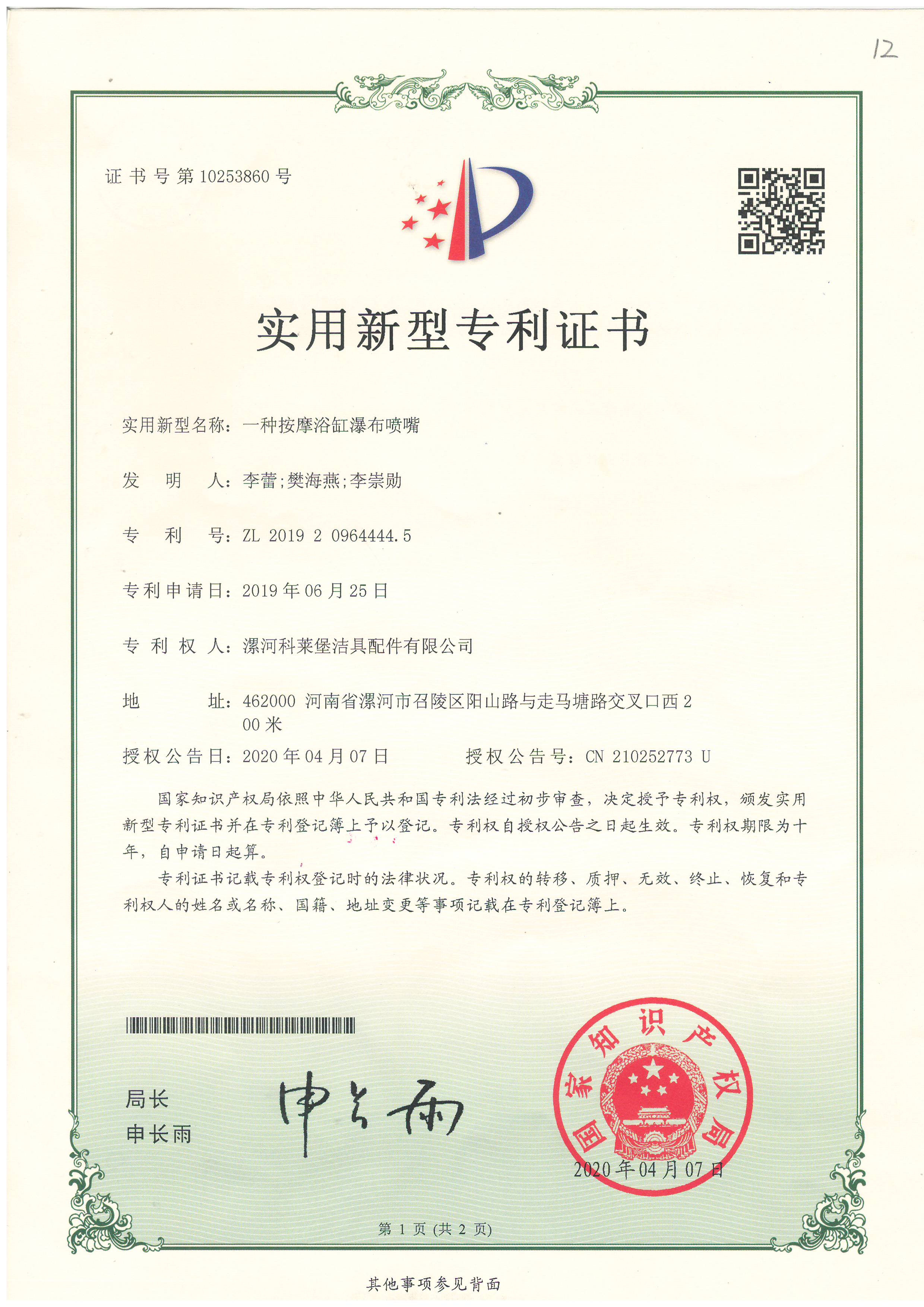

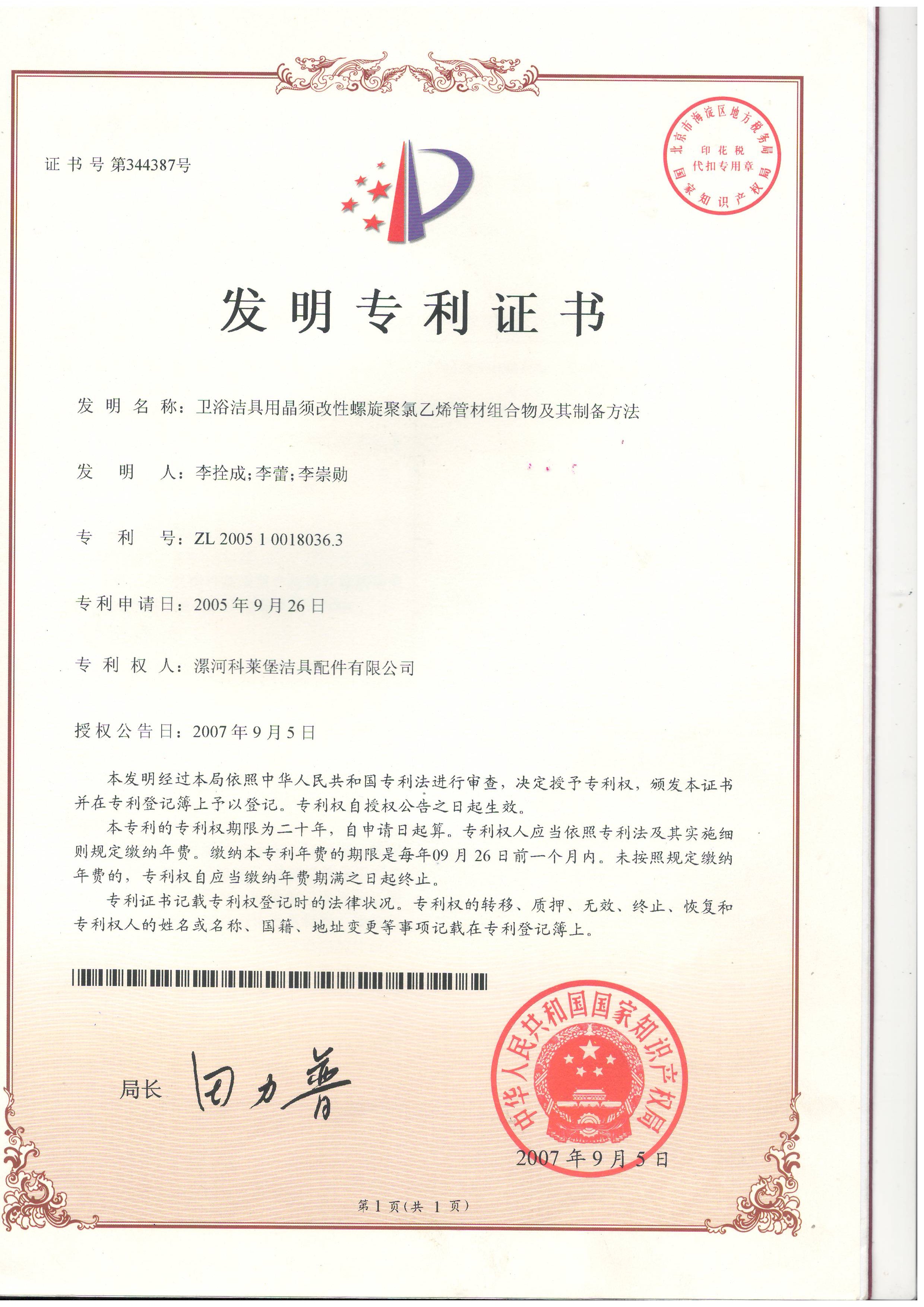

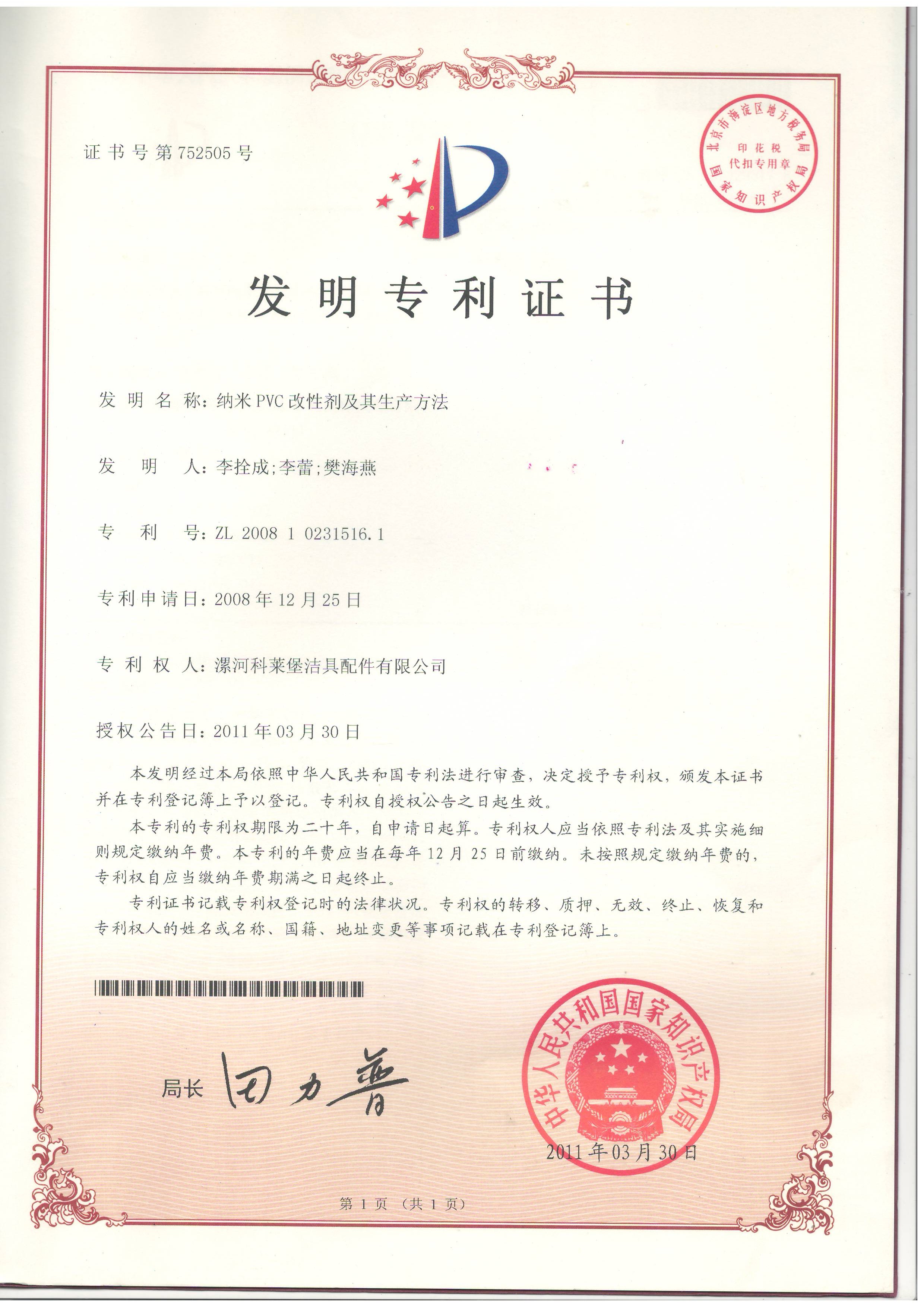

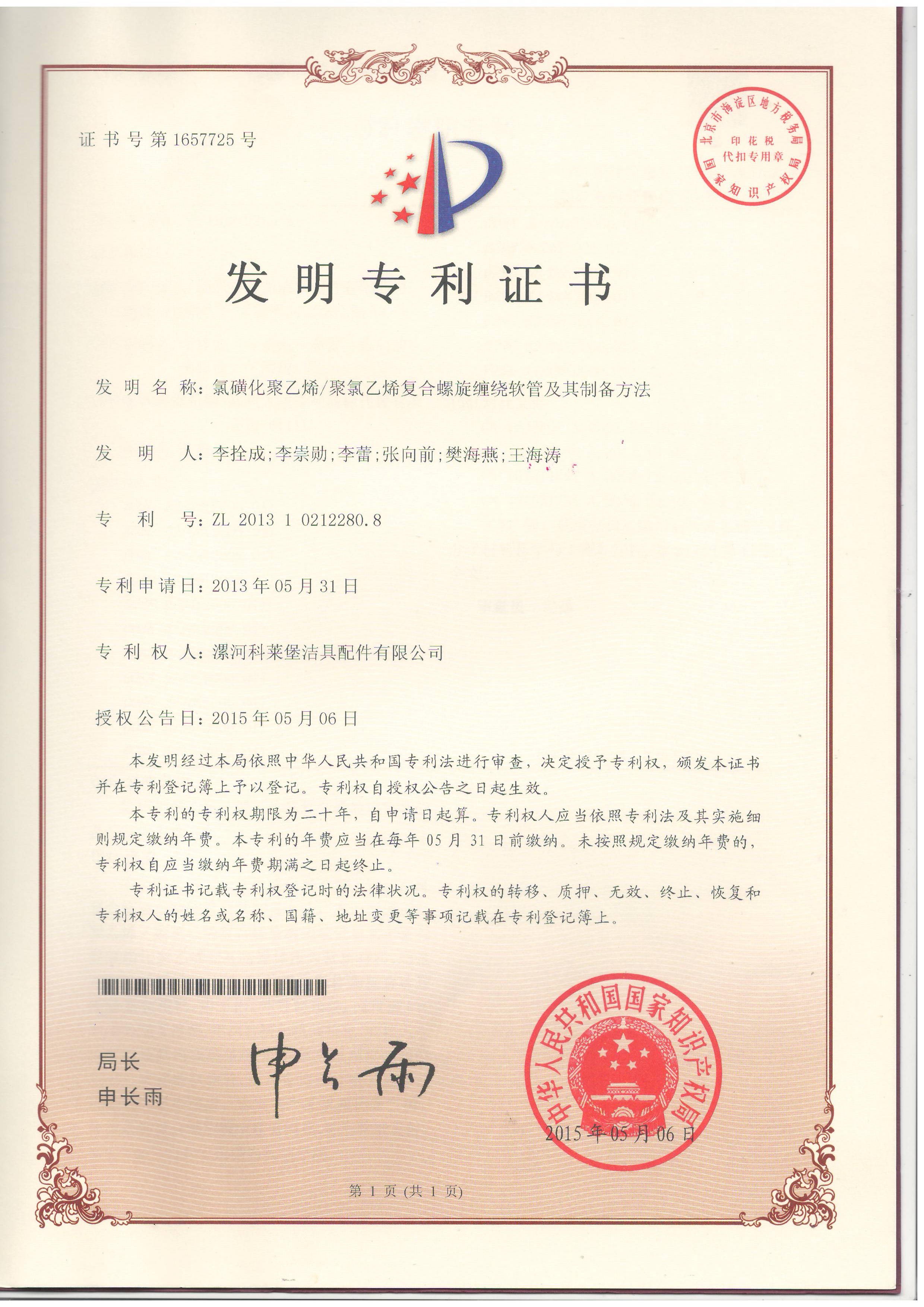

Certificates

1.png)

3-213x300.png)

1.png)

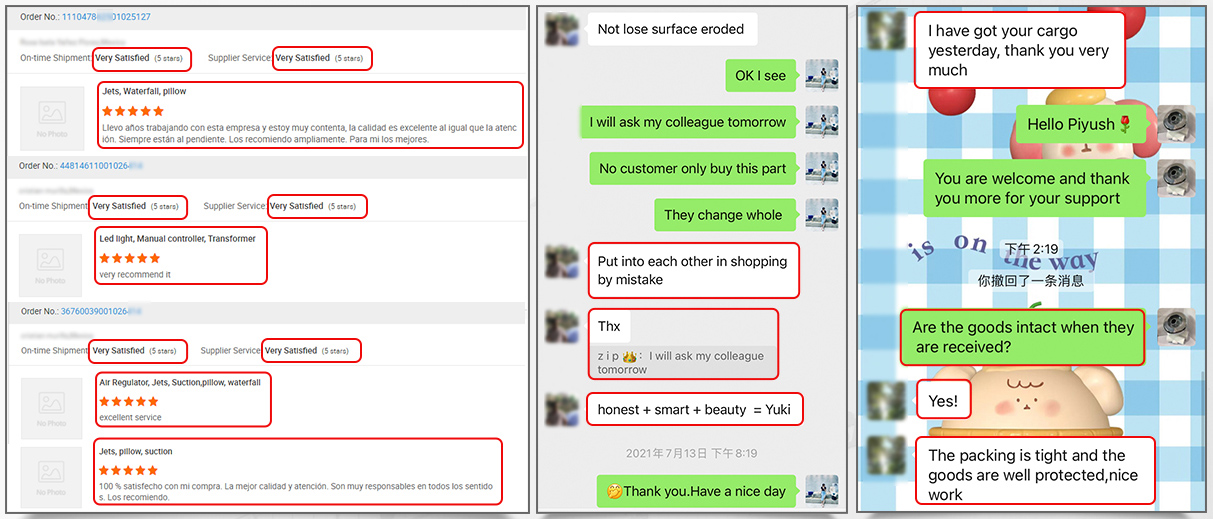

Customer Feedback

Photos of Exhibition Customers Collection

Welcome to Visit Our Factory

News

Table top chain from Luohe Global Technology Co.,Ltd

our company Luohe Global Technology Co.,Ltd is dedicated in conveyor belts and conveyor components for 17 years. With SGS certificate,accept OEM and ODM.

When it comes to moving ore during the mining process, it can be challenging to understand the best methods. Conveyor chains are the solution to moving products under harsh conditions. They allow movement of heavy or difficult material requiring high torque, and high speed in otherwise unforgiving conditions. Figuring out which one works best for a project can require a bit of expertise, which is where Bit Service comes in.

1. What are table top chain?

table top chain offer many advantages over conventional conveyor belt systems. These belts offer sturdy yet flexible design features, which are increasingly used for food processing industries.

We offer a wide range of table top chain with many different designs. A table top chain conveyor is easy to picture. This conveyor system provides a flat, table-like surface on which boxes, products, and other goods can be placed for easy transport across a warehouse.

All table top chain conveyors are automated, using a motor to drive the belt along so that the products can be swiftly moved. Compare this to the roller conveyors used in some operations, which do not provide a flat or smooth surface and can be either manual or automated.

Our team will help you identify the optimal solution for your particular needs and give Product according to that.

Table top plastic chains are made of engineering plastic and are connected using stainless steel pins,The plastic tabletop chains constitute a light-weight yet strong and silent alternative to steel chains.

These chanis are used mainly in the food and packaging industry for conveying many kinds of containers. For example: PET bottle,pet petaloid bottle,aluminum and steel can,cartons,trays,packaged products (cartons,shrink packs),glass,plastic containers.

1. What are Benefits of table top chain?

- Engineered for a wide range of conveyor applications for many industries

2.Straight-running and side-flexing options for ease of installation, reduced floor space

3.Accommodate unique application environments with innovative surface options

4.Narrow TableTop Chain widths for multiple-strand and variable-speed conveyors

5.Continuous conveying surface for greater-width-requirement MatTop Chain applications

6.Assembled-to-width MatTop Chain configurations for custom sizes

7.Reduce container tipping and jams at transfer points

8.TableTop Chain for high-strength and high-speed applications

9.accuracy of molding process guarantees optimum flatness

10.high wear resistance and low friction

11.high working load

Main Application: Food and Beverage, Conveying Lines for PET bottles, Aluminium or Steel Cans, Packaging Lines

* 820 Single Hinge Straight Running Table Top Chain Conveyor

* 821 Double Hinge Straight Running Table Chain Conveyors

* 880 Side Flexing Slat Top Chains Conveyor

The Table Top Chain Conveyor System is Consisted of Slat Top Chains, Gear Motors, Sprockets, and assembled with Tube Support Legs, Guide Brackets Profiles, Wear Strips, Chain Tracks, etc. The system is running in low friction and co-efficient, which would be ideal solution for you production line transmission.

* The table top chain are widely used in Lines for Food and Beverages, Dairy Milk, Beer, Edible & Olive Oil Packaging, Agriculture, Fruits Washing Sorting and Grading;

* There are also conveying solutions for for Packaging Machinery, Labeling, Bottling Canning Filling, Crate Carton Filling, Empty Keg Lines and Case Conveyors, Low Back Pressure LBP Chains for Products Accumulation etc.

How do table top chain conveyors work?

The table top chain conveyor design may sound simple, but it’s actually a bit more complex than most roller and skate conveyors because these systems always require a power source and driver.

Table top chain conveyors consist of a few key components: The motor, which drives the belt along, and the belt itself, which generally provides a flat, solid surface with no gaps or holes. The material of the belt varies depending on the model you purchase, and IFS stocks a variety of belt types.

What products are suitable for table top chain conveyors?

The design of a table top conveyor allows a number of products to be securely transported from one place in the warehouse to another. Unlike a roller or skate conveyor, table top conveyors can hold an item upright and securely transport smaller items since there aren’t any large holes or gaps on the surface.

For this reason, table top conveyors are the most versatile of all conveyor systems and can transport a wide variety of products, including:

Large items, such as boxes and luggage.

Small items, including items that would get stuck between rollers.

Odd-shape items, like those that might get jammed between rollers or fall off a non-flat conveyor system.

Containers, especially those that need to be held upright as they move from one phase to the next.

Generally, any item that may be lost, damaged, tipped over, or potentially get stuck in a roller or skate wheel conveyor system would be best served by a flat top conveyor.

Why should I choose a table top chain conveyor system from Luohe Global Technology Co.,Ltd?

In order to process such a wide variety of products, Luohe Global Technology Co.,Ltd offers table top conveyors made using a variety of belt materials. While a plastic table top chain conveyor is cost-effective and fits a variety of needs, we also manufacture chemical-resistant belts, sanitary belts, and heat-resistant belts to service our clients across industries.

Aside from the sheer number of options, Luohe Global Technology Co.,Ltd is also the preferred provider of table top conveyor systems because of our experience in the industry. We boast over 700 packaging machines in our catalog, which are designed using a modular system to create your ideal production line solution.

Luohe Global Technology Co.,Ltd is backed by engineers with decades of experience and we have satisfied clients in more than 50 countries, with projects totalling over $100M in installations. Furthermore, all of our machinery is designed and fabricated by our team in china.

Lastly, if you’re concerned about not being able to find table top chain conveyor parts after the installation, there’s no need to worry: Our team services all of our machinery, which is why we’re one of the leading table top chain conveyor manufacturers in the world.